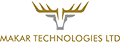

New SMT Line – Increased Capacity

As we continue to grow and expand as a UK manufacturer, we are consistently investing in new and improved machinery and equipment. Our latest investment is an additional, high-speed SMT placement line in order to increase our PCB assembly capacity.

The new line will allow us to support the growing requirements of both new and existing customers across a range of market sectors. Our new line comprises of 2x Mirae pick and place machines and a Falcon inline AOI (Automated Optical Inspection) machine. This provides a number of key features including:

- Placement capacity of 92,000 components per hour (cph)

- Ability to place fine-pitch surface mount components

- 160 component feeder lanes based on 8mm wide feeders (minimising set-up downtime for heavily populated PCB’s

Our customers can now take advantage of our increased efficiency, flexibility and higher overall production capabilities.

David King, Makar Technologies Managing Director, comments:

“We are all pleased to see our Forres manufacturing site continue to grow after lots of hard work and effort. The increased volumes from our existing, loyal customer base coupled with new customer orders gives us the confidence to progress with further investment and boost our offering, including our new SMT line. Over the coming months, we have further exciting investment and expansion planned which we hope to soon announce”

Please take a look at our PCB assembly and product assembly pages for more information on our capabilities.

Our team are always here to support any queries you may have. Please send any RFQ’s through to enquiries@makartechnologies.com or get in touch on our contact page.

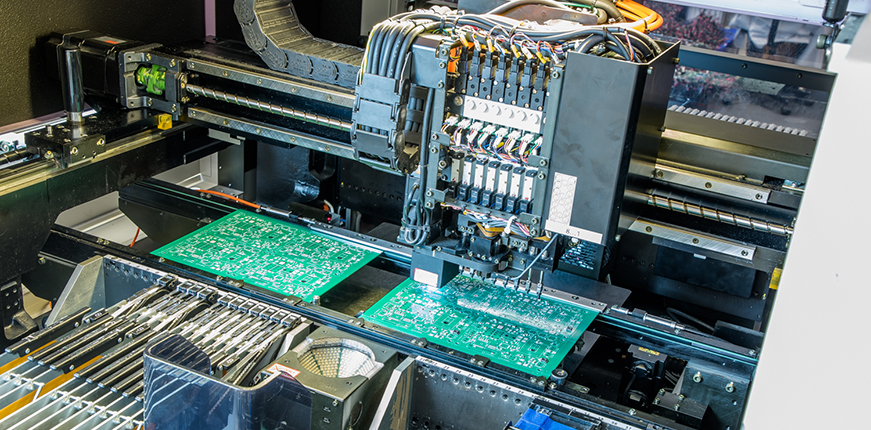

University of the Highlands & Islands

We recently welcomed 16 engineering students plus lecturers from the University of the Highlands & Islands (Moray) to our Forres facility.

As we continue to grow, we are always on the lookout for young and enthusiastic graduates to join our experienced team. This visit allowed local students to gain an understanding of the potential jobs available to them in the area (Highlands/Moray of Scotland).

Throughout the visit, our team presented the top of the range machinery and processes that are carried out on a daily basis at Makar. From Surface Mount Technology through to Final Product Testing, our manufacturing facility provides exciting opportunities for newly qualified engineers and technicians.

The ability to meet individuals in different engineering roles proved very beneficial. The students asked questions about their experiences in the industry and their pathway to the positions they are now in. Our design engineers cover a number of disciplines including electronic, software/firmware and mechanical design.

Having a number of UHI graduates already working for the company, David King (Managing Director) is extremely happy with their contribution and progression so far.

“Makar are developing exciting new products and technologies. Creative minds in the local area will only help us push the boundaries of innovation.”

We welcome further collaboration with educational institutes and will continue to grow our relationship with UHI (University of the Highlands & Islands)

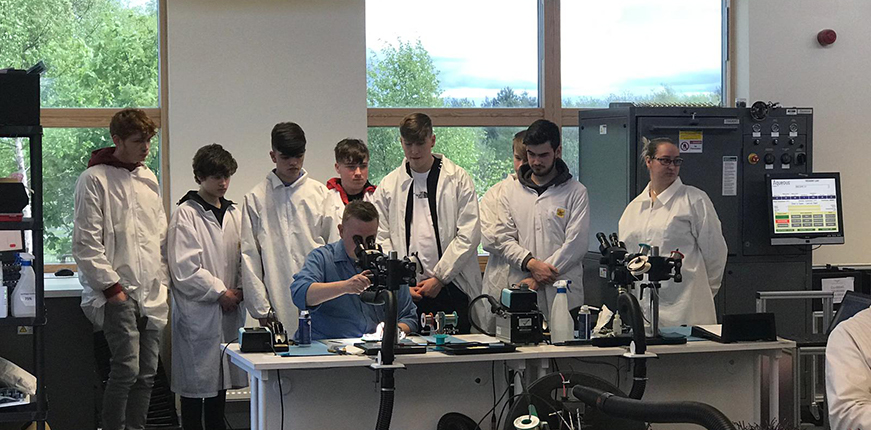

The Printed Circuit Board

Makar Technologies featured in this months edition (February) of the Knock News magazine, with a captivating article based around the printed circuit board.

Knock News is an independent local magazine that is ‘quirky and original’, founded by David Gordon in 2007.

We welcomed David and Richard Oakley, the author of the Makar Technologies article, into our factory for an insightful view on our innovative developments.

The article goes into fine detail of some of the internal processes used to build a printed circuit board, as well as providing an overview of electronics design and manufacture in general.

Makar Technologies Ltd currently has a full order book and was working on projects to remotely control caravans and a stair-lift during our visit, Dave King says that if you require a system to be controlled, they can also provide the control electronics, actuators and computer systems to bring the project to life. They are what industry describes as a ‘turn-key supplier’, they do everything simply leaving the customer the starting key. Customers can have systems designed with or without any specification in mind. The Makar design team would then look to generate PCB designs, giving costing, functionality and future proofing suggestions before negotiating with the client the final design. This may or may not involve building prototypes for the customer’s approval. Makar’s engineers are capable of writing software for controlling system operation, for example, the firmware to control the speed and torque delivery of an electric motor. Makar are also currently looking to increase the functionality of their equipment by building smart intelligence into the equipment.

For a better understanding of our industry, we would highly recommend taking the time to read the knowledgeable article which can be found below:

http://www.knocknews.net/featured/makar-technologies-extended

You can also download a copy of the magazine here.

Our Capabilities

For further information on our printed circuit board capabilities, please take a look at our PCB Assembly page.

New Website Launched

Going into the New Year (2019) our aim is to improve your experience in sourcing information about Makar Technologies. Along with the the new website launch, we have new brochures which provide you with more detail on our capabilities.

Download our new brochure here.

Toyota Mobility Finalists

We are happy to announce that we have partnered with Phoenix Instinct to design and manufacture an intelligent wheelchair.

Our Managing Director, David King, supported Andrew Slorance in the Toyota Mobility competition. Phoenix Instinct have reached the final along with 4 other companies who have all received $500K funding each.

Makar Technologies will be designing and manufacturing the electro-mechanical sub-systems as part of the final proposed solution.

A link and further information on the finalists can be found below:

The Phoenix AI wheelchair is an ultra-lightweight manual wheelchair made from carbon-fiber. Using smart sensors the chair will configure itself to what the user is doing so it remains in sync with how the user moves. The sensors detect if the user is leaning forward or back, algorithms will calculate the wheelchair’s response. The Phoenix Ai will have many smart functions never before seen in wheelchairs, at the core is intelligent centre of gravity. The chair will continually adjust its centre of gravity to fit what the user is doing making for a chair that is easier to push and turn by eliminating drag and uncomfortable, painful vibration while also making the chair safe from falling backwards. Intelligent, lightweight power assist will make slopes easier to ascend while automatic braking will remove the need for users to grip the wheels to slow down.

As a company, we are very passionate about this market and continue to support other applications with innovative designs and manufacturing.

Farnborough Airshow 2018

Our motor drive products were being showcased and attracted a lot if interest. We are thankful to all who stopped by for a chat.

The stag and whisky tasting proved a big hit, we will need to keep this in mind for our next exhibition!

Please feel free to get in touch with any questions regarding our product range or services offered. Our friendly team will be happy to support in any way.