“High Quality is Always at the Top of our Agenda” – Continuous Improvement Drives Makar’s Manufacturing Quality & Reliability

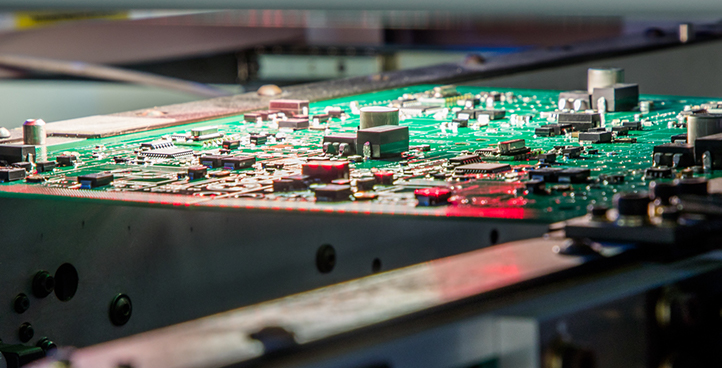

As part of our PCB assembly process, we operate in-line Automated Optical Inspection (AOI) on all of our production lines. AOI enables fast and accurate inspection of electronic assemblies, in particular PCBA’s, therefore ensuring optimum workmanship quality.

What is AOI and what does it inspect?

These advanced inspection machines can fully inspect a densely populated PCB Assembly in a matter of seconds, carrying out:

Component Inspection Tests

- Checking for missing, reversed, shifted, damaged, skewed, and tomb stoned components.

- Checking polarity and marking of components (identifications, signs, colour etc)

Solder Inspection Tests

- Checking for no solder, insufficient/extra solder, solder bridging and flux deposits.

It’s an extremely powerful solution to quickly identify defects and ensure the highest quality of our manufacturing process. Our In-line AOI systems are placed just after our reflow process on our surface mount lines.

One of the key elements of an Automated Optical Inspection system is the image capture. The high resolution camera system takes an image of every component. This is then analysed by complex algorithms searching for the defects mentioned above.

Before processing all boards through the AOI, we pass a “Golden Board” through so that the system can learn the relevant attributes. This “Golden Board” is a known working board which has passed functional testing and a First Article Inspection.

Based on the golden board, differences, abnormalities or even errors can then be clearly indicated by the AOI’s built in processing software. We record all results for PCBs in a database, which we can then analyse in-depth.

So, how does this benefit our customers?

- Zero/extremely low defect quantity, resulting in high quality, consistent output for our customers

- High pass rate for functional testing, therefore improving efficiencies and reducing customers testing downtime.

Please take a look at our PCB assembly and product assembly pages for more information on our capabilities.

Our team are always here to support any queries you may have. Please send any RFQ’s or questions through to enquiries@makartechnologies.com or get in touch on our contact page.